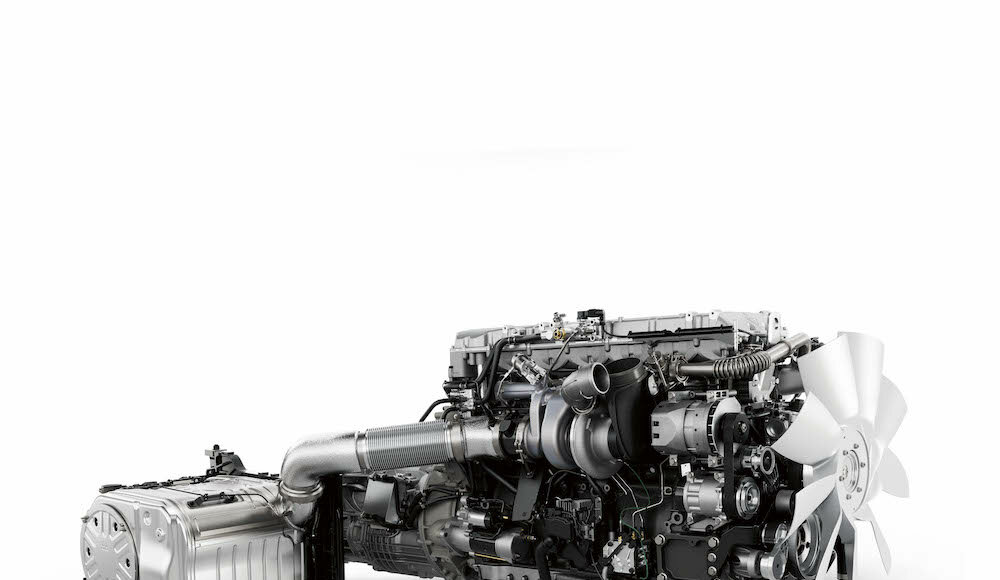

Navistar Inc. has started production on its new International S13 Integrated Powertrain at the company’s Huntsville plant. To accommodate the new production, the plant was expanded by 110,000 square feet.

With the new addition, the plant now has 410,000 square feet and two assembly lines, one for the T14 transmission and the other for the S13 engine. The plant also has three major machining lines. Overall, Navistar has invested more than $200 million in its Huntsville facility, which was established in 2008. It now employs more than 230 skilled workers.

“We’re thrilled to unveil the expansion of our Huntsville Powertrain Plant, symbolizing our commitment to innovation and excellence. Through collaborative efforts with the Traton Group, we are confident to set a new efficiency benchmark in sustainable transportation,” said Brandon Tucker, director of operations, Huntsville Powertrain Plant.

The expansion began back in February 2020 and has added roughly 100 jobs to the plant. In addition, several manufacturing processes have been improved by installing robotic assembly cells, enterprise connected manufacturing devices with advanced error proofing, and automated guided vehicles that allow the plant flexibility when needed. The plant also added LED lighting, a wastewater evaporator to minimize wastewater discharge and new augers to separate recyclables from rubbish to significantly reduce the waste going to the landfill. The S13 Integrated powertrain achieves advanced fuel efficiency and performance.