State and local officials gathered with officials of Westwater Resources Inc. today to announce plans for a first-of-its-kind graphite processing plant in Coosa County.

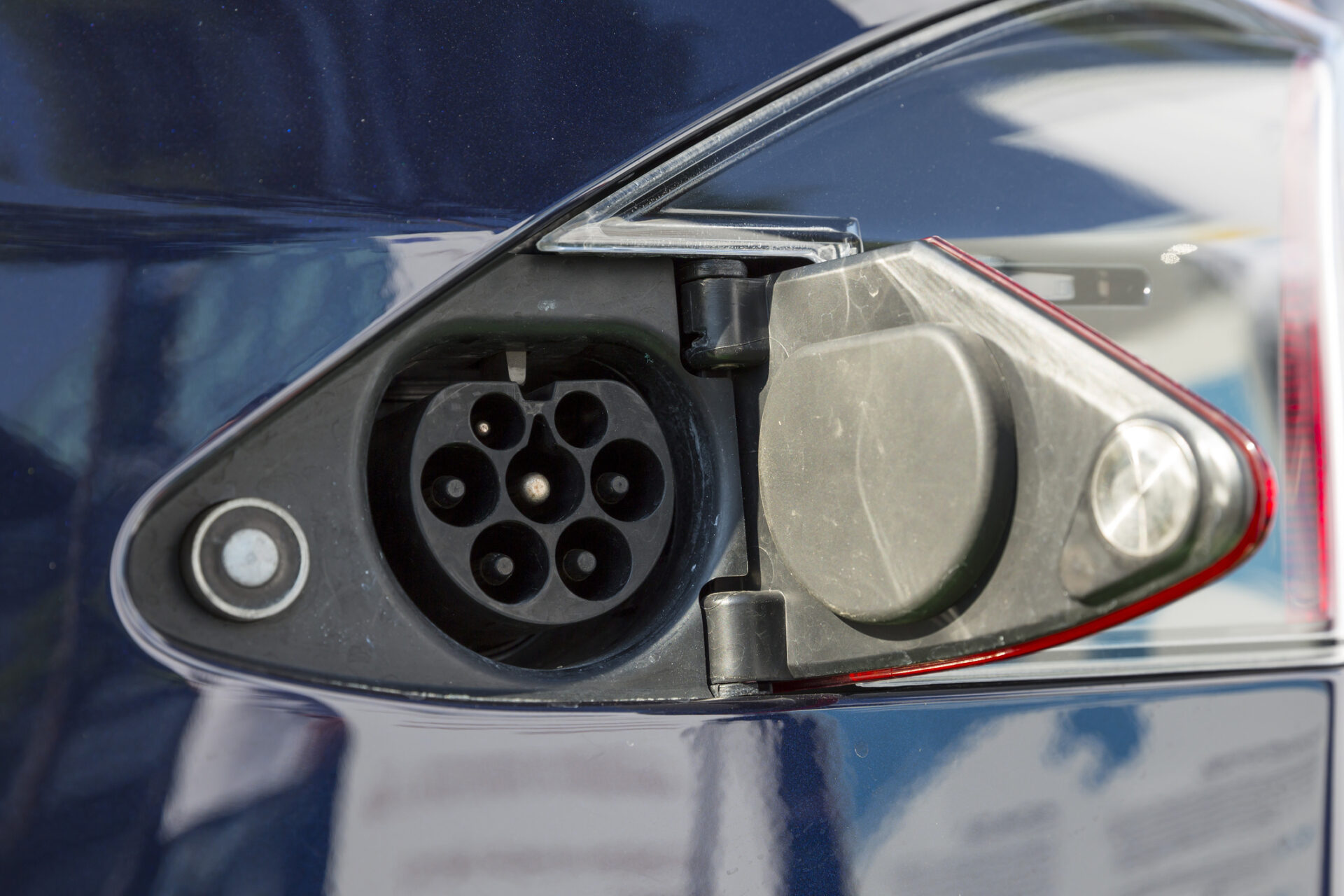

Gov. Kay Ivey signed an incentives agreement for the plant, which will produce a key component of lithium-ion batteries. Graphite is also used as a conductivity enhancer for other types of batteries, including lead-acid batteries used in traditional vehicles.

Colorado-based Westwater owns 40,000 acres of mineral rights, where it expects to mine graphite beginning in 2028, Chris Jones, president and CEO, told shareholders. In the meantime, it will obtain “non-Chinese feedstock” with plans to begin production in Alabama this year.

When the firm gave up its uranium interests in favor of graphite last year, Jones explained to shareholders: “Graphite is an important material necessary for modern life — it’s in your smartphone, your laptop, your car and your smoke detectors and flashlights. It is what makes lithium ion batteries work — and provides performance enhancements for all other types of batteries.”

Westwater plans an investment of $80 million or more in the graphite processing plant, through its subsidiary Alabama Graphite Products LLC. Slated to be in production by the end of 2022, the plant will be in Kellyton, near Alexander City. A second phase is expected to bring total investment to $124 million.

The plant is expected to employ at least 100 full-time workers with an average hourly wage of $21.15.

“This plant not only will make Alabama the U.S. leader in graphite production, the go-to place for this important resource in battery manufacturing, it also will elevate our standing even more as a major player in the fast-growing electric vehicle sector,” said Ivey. “We’re home to four major auto plants, and the ability to source precious materials in state for the lithium-ion batteries used in electric and hybrid vehicles will be a big plus in attracting other manufacturing jobs to the state.”

The state will provide about $29.9 million in jobs and tax credits over the next 15 years. Also, AIDT will provide assistance with employee training and recruiting. Local incentives total about $4.7 million.

The federal government has declared graphite to be critical to the nation’s economy and national security, Jones noted.

“All of the graphite used and needed in the United States, including by America’s auto industry, is imported,” he said. “Most of it is from China, where media have reported both worker and environmental issues. Domestic production of graphite reduces our dependence on foreign sources. Even though the raw graphite we will process into battery-grade material will be imported initially, none of it will be from China. We have secured agreements from other providers.”

Alabama Graphite plans to use a proprietary process to purify and refine the graphite, explaining that their process “is safer and more environmentally friendly and sustainable than the hydrofluoric acid-based process commonly used in China and elsewhere that uses more water and produces more environment-damaging byproducts.”

“One of our core values is safety. We’re protective of our workers, the community and the environment,” Jones said. “Whether it’s mining or processing graphite, our company is committed to doing it in an environmentally safe, sustainable manner. The biggest virtue of electric vehicles and other battery-powered products is they reduce carbon emissions and are better for the environment. Producing the key materials for those batteries, we believe, can and should be done in an environmentally responsible way as well.”