Huntsville-based Aerobotix has made an agreement with Minteq International Inc. to distribute Minteq’s FIREX RX-2390 thermal protection system coating for hypersonic flight hardware. Aerobotix will work directly with Minteq’s Pennsylvania-based Pyrogenics Group, a leader in high-temperature coatings for military and aerospace applications.

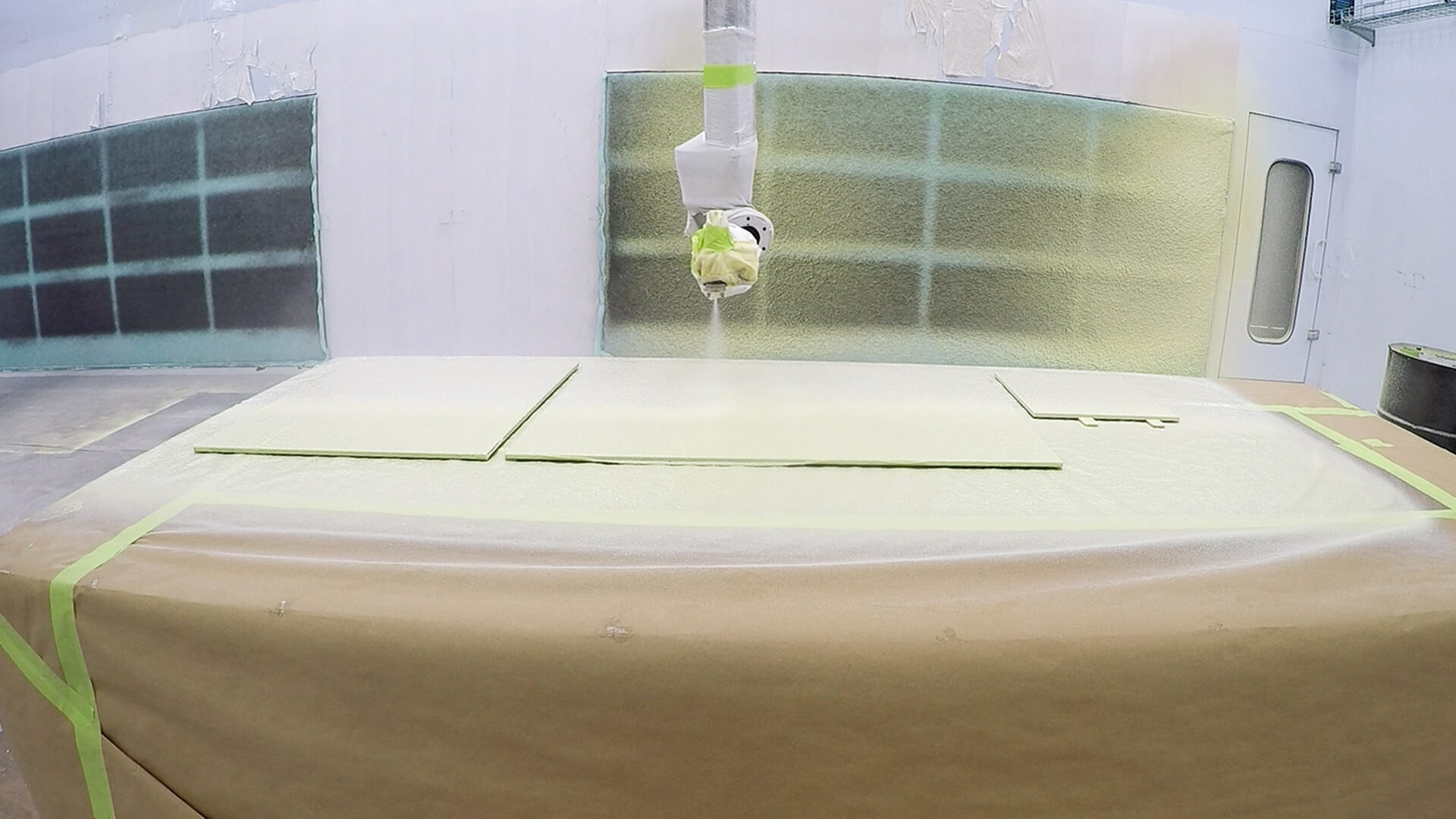

Aerobotix’s expertise is in robotically spraying parts and test panels within extremely tight tolerances for uniformity and thickness of coverage. The agreement enhances the company’s new fully automated hypersonic coating production system.

“Our desire was to assist our customers and the U.S. government in fielding hypersonic missiles and aircraft as quickly as possible. By making the commitment to keep fresh FIREX RX-2390 on our shelves, we can immediately assist the major programs by robotically spraying accurate panels and even prototype parts for flight tests,” said Kent Pfeifer, Aerobotix’s process development manager.

Aerobotix and Minteq worked together to develop a FIREX RX-2390 recipe and a unique robotic paint dispensing system that is optimized for automation and heavy production. The formulations combine modified epoxy binders with thermally active materials that form cooling gases when exposed to temperatures in excess of 350 degrees Fahrenheit.

“Aerobotix is spraying our product so much better than could ever be done by hand. The robot is mixing the coating perfectly, just in time, and applying it so accurately — we are seeing improved performance across the board,” said Mark Breloff, Minteq technical sales manager. “Aerobotix can scan the part to get the as-built shape, spray to near-net and then use the robot to sand down to the optimal shape and thickness.”