When a European Tier 1 automotive manufacturer launched a major new program in Alabama, they faced a significant production challenge: 28 unique stampings requiring fastener projection welding and clinch press applications, with an annual volume of 240,000 vehicles. They planned on running two shifts, five days a week, to fulfill the production requirements. Traditionally, their operations relied on manually operated “nut farm” cells, labour-intensive setups where operators load and unload each part by hand.

To meet the demands of this high-volume program while improving efficiency, the manufacturer partnered with CenterLine Southeast to implement a smarter, more automated solution.

A Robotic Approach to Fastener Application

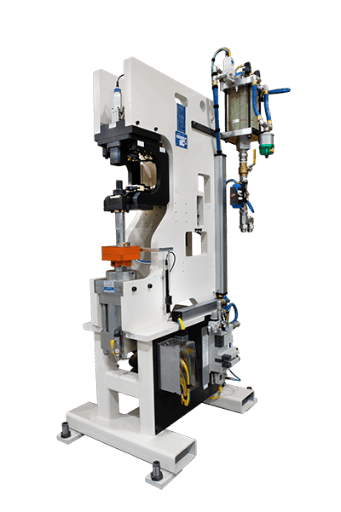

CenterLine proposed a fully robotic process, High Speed Fastener Solution™ (HFSF), that combined three key technologies:

- The PinPoint™ Solution for intelligent part feeding

- SoftMount™ projection weld guns and clinch presses, each dedicated to a unique fastener

- and an exit finished part conveyor that isolates finished parts to prevent mixed workpieces.

An HSFS was designed for each of the three robotic cells to meet the production requirements.

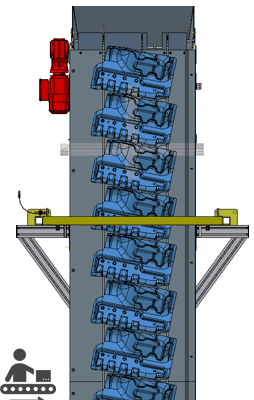

PinPoint™ Solution: Intelligent, Uninterrupted Supply of Workpieces

At the front of the cell is the PinPoint™ Solution, a distinctive system that can feed many different stampings into a robotic cell. Operators load workpieces onto drive pins using a locating hole. As the workpieces advance, the PinPoint’s top surface orients them by friction and a simple guide at the robot’s pick position. A pattern-matching camera verifies each workpiece’s orientation before the robot picks the part. If a workpiece fails inspection, it automatically rolls off the front of the PinPoint, keeping production moving without disruption. This intelligent buffering system allows operators to monitor multiple machines at once, reducing stress and increasing productivity.

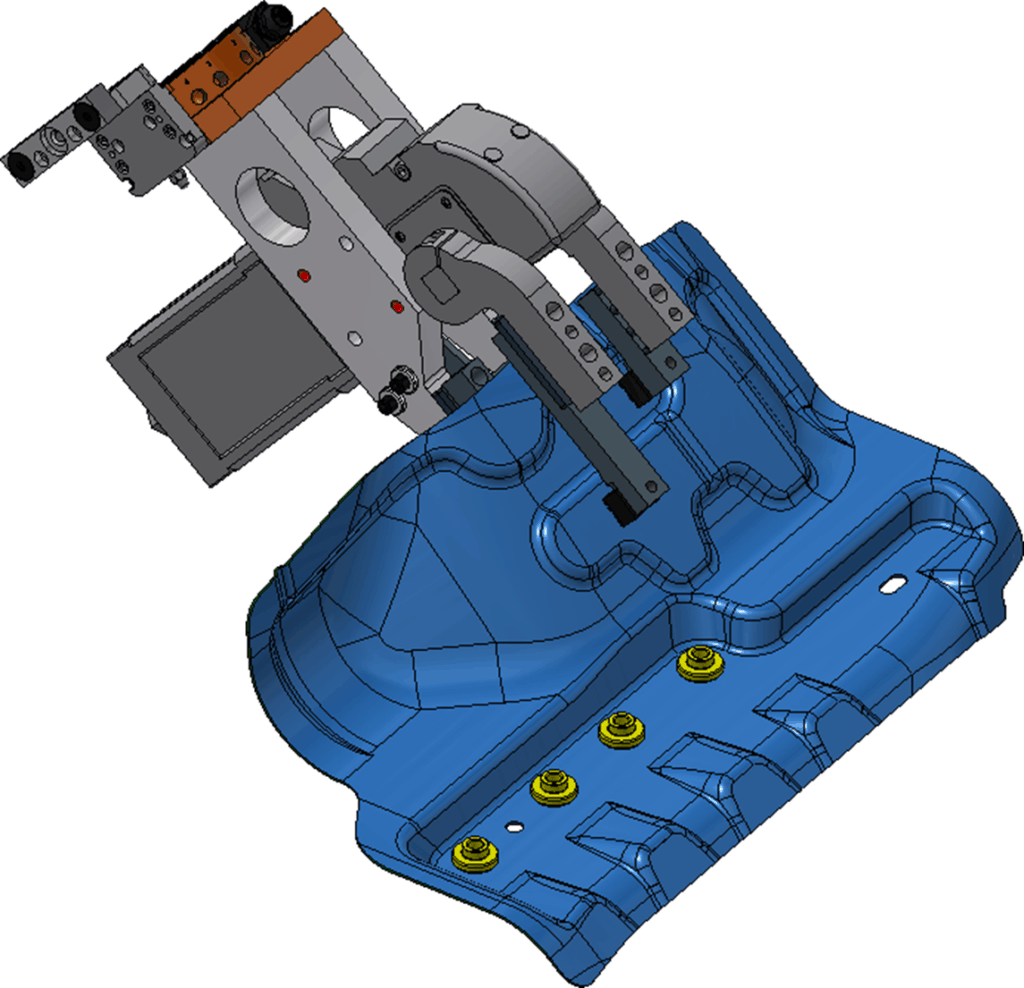

Example of a Stamping Robot Gripper

SoftMount™ Weld Guns and Presses: Fastener Precision and Stability

Teaching a robot to present the stamping hole to an upper weld or clinch pin is a complex task, but CenterLine’s SoftMount™ systems are designed to mechanically fine-adjust their position to a stamped hole, ensuring consistent projection welding or clinching of a fastener. CenterLine, by inverting the traditional process— loading the stamping to the upper pin while the fastener is loaded to the lower pin—significantly saves 1.5 seconds of fastener feed time per cycle, enhancing the overall efficiency of the process for the Tier 1 manufacturer.

Results That Speak for Themselves

With this integrated solution, the Tier 1 manufacturer achieved a highly flexible, high-speed production line capable of handling CenterLine’s variation with minimal operator intervention. The result: uninterrupted production, reduced labour requirements, and a more efficient path to meeting their volume targets.