In today’s competitive automotive landscape, precision and reliability aren’t just expectations; they’re reputational cornerstones. A leading European OEM is raising the bar with a new platform focused on performance, functionality, and long-term durability. This initiative challenges Tier One suppliers to adopt smart systems that move beyond traditional, experience-based manufacturing methods.

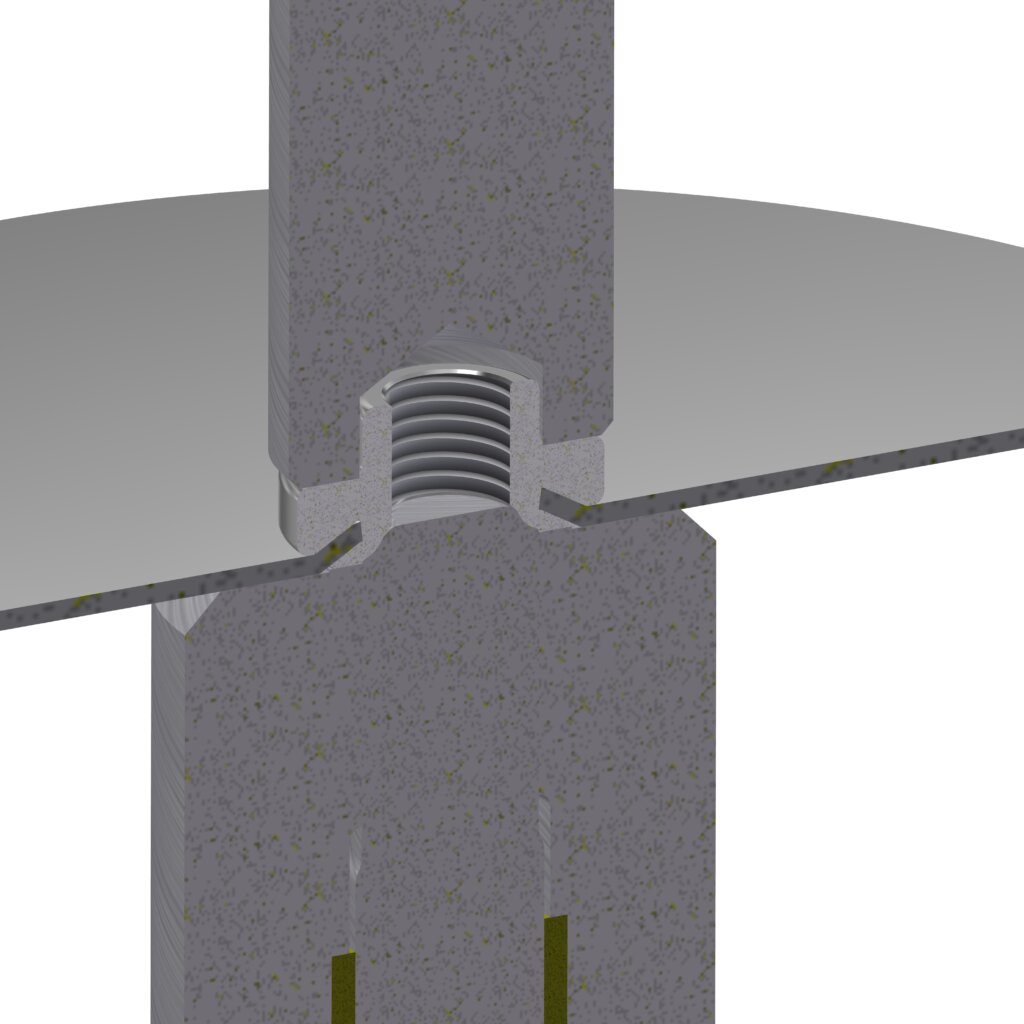

A Tier One manufacturer chose CenterLine to develop a clinch fastener installation process for rocker panel assemblies, a critical structural component prone to corrosion from moisture and road debris. To address this, a water-tight sealing fastener capable of high installation quality was selected by the OEM. But ensuring long-term performance requires more than just the right fastener; it demands a process that can monitor the installation quality.

The Challenge: Invisible Defects

Fastener holes are punched and formed during the stamping process to create a pre-formed profile, essential for meeting quality specifications. However, variations in hole quality stemming from stamping tool wear, die setup, multi-stage forming practices, press alignment, and even differences in material thickness and strength can introduce inconsistencies that visual inspection alone can’t reliably detect.

The VersaForce™ Advantage

CenterLine’s patented VersaForce™ Clinch Press addresses this challenge with optimized motion control, precise force delivery, and real-time process monitoring. This integration-ready solution features a servo-pump-driven actuator that delivers high clinching force efficiently, operating only on demand, while built-in VeriFast™ SA (Signature Analysis) continuously validates each installation using closed-loop force vs. distance feedback. This ensures that any deviation, even those not visible, is detected and alerted before a quality event.

Real-World Case

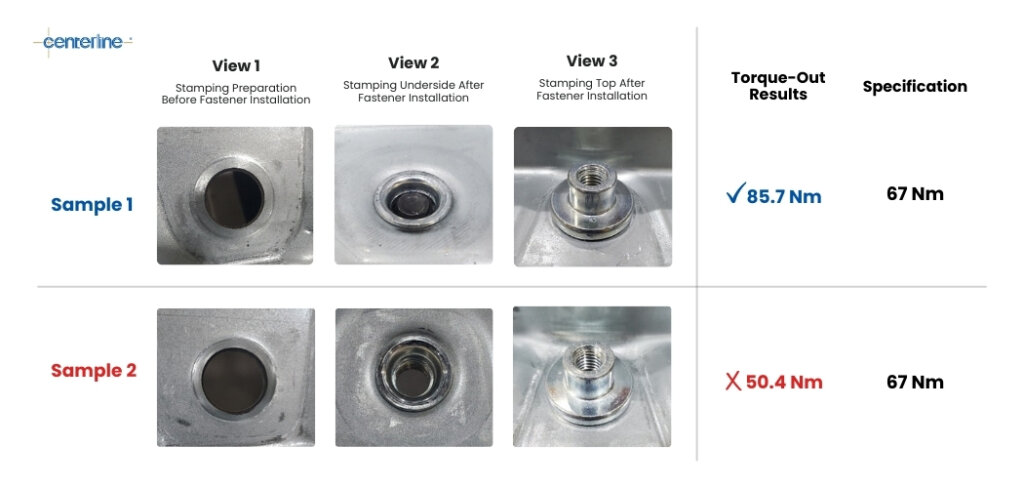

During development with a Tier One supplier, an early revision of the stamped part (Sample 1), featuring well-formed fastener holes, was used to define the VeriFast™ SA teach signatures and establish the process monitoring window. Destruct testing confirmed strong performance, consistently meeting customer specifications.

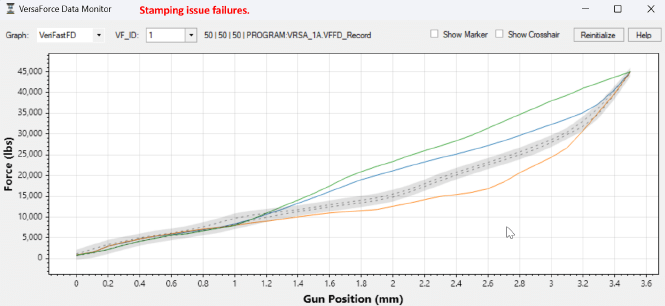

When a new revision (Sample 2) was introduced, our VersaForce Clinch Press with VeriFast™ SA immediately flagged the parts as non-conforming. The force vs. distance signatures fell outside the taught envelope, indicating a change in the stamping prep. Later, through (Sample 2) destructive testing, the new parts failed to meet specifications. Although the visual differences were subtle, the system detected a meaningful shift in process quality.

The accompanying graph shows the VeriFast™ SA tolerance band in grey, created based on validated parts, with green, blue, and yellow traces from the failed samples falling outside. The three-view image comparison further illustrates this: the pre-formed hole in Sample 1 is centered and formed to specification, while Sample 2 shows misalignment and improper form, deviating from the fastener manufacturer’s guidelines. Yet, once the fastener is installed, the top and underside views appear nearly identical, reinforcing the importance of real-time process monitoring to catch what visual inspection can’t.

By identifying the issue early, we helped the customer trace the problem to a change in the stamping process and avoid a potential quality event. CenterLine, well known in the industry for building quality machines with integrated process monitoring, was proud to support the OEM in maintaining high standards and delivering consistent part quality.

If you’re looking to enhance your manufacturing processes with intelligent automation and precision analytics, CenterLine is here to help. Let’s build your reputation, one signature at a time. Contact us!